Different Types of Fuel Pumps in a Tractor: Inline, Rotary and CRDI

Table of Contents

- What is the Role and Importance of a Fuel Pump?

- What are the Types of Fuel Pumps in Tractors?

- Maintenance and Troubleshooting of Fuel Pumps

What is the Role and Importance of a Fuel Pump?

A fuel pump is among the most crucial components of a diesel engine. It delivers the required amount of high-pressure fuel to the engine at the right time and in the adequate amount. Timing gears drive the fuel pump, which is controlled using the foot or hand accelerator of the tractor.

The fuel pump ensures the engine receives a consistent and controlled fuel supply, allowing it to operate at peak performance. So, it is the main component responsible for precise fuel delivery so that the engine runs smoothly. Timely and metered fuel delivery is important as it directly impacts the power output, emissions and efficiency of the engine. Modern diesel engines use fuel injectors to directly inject pressurised fuel into the combustion chamber of the engine. It is also known as the Direct Injection (DI) method.

What are the Types of Fuel Pumps in Tractors?

Even though there are different types of fuel pumps, they have the same purpose, which is moving fuel from the tank to the combustion chamber. There are mainly three types of fuel pumps used in tractors: inline fuel pump, rotary fuel pump, and CRDI fuel pump.

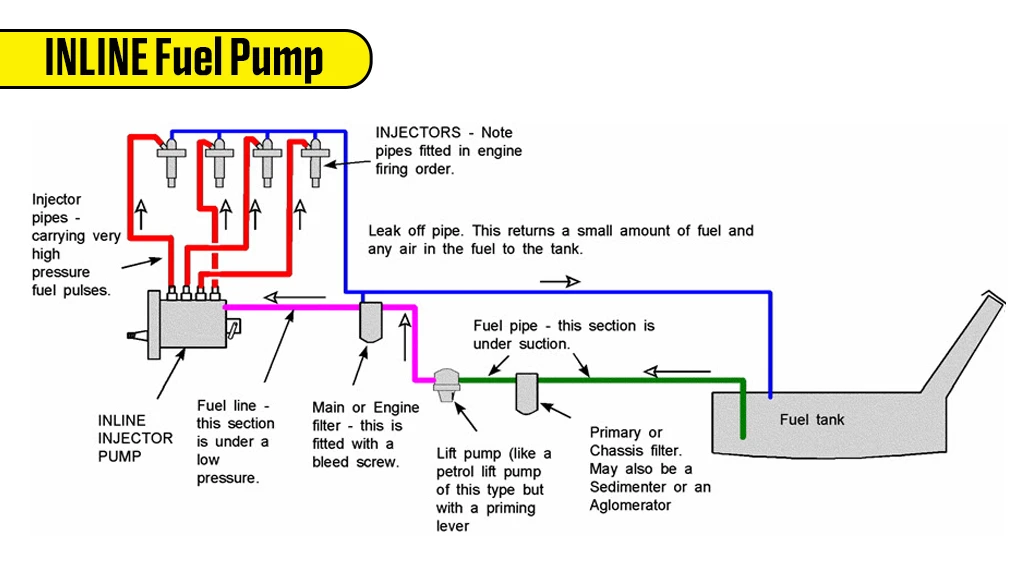

Inline Fuel Pump

Inline pumps are known for their reliability and are common in older tractor models. All the engine cylinders have a combination of a pump and plunger fitted to them. The plunger pressurises the fuel to be injected into the combustion chambers with the help of fuel injectors. A camshaft operates the plunger by using power from the crankshaft. It generates suitable force to move the plunger back and forth and pump the fuel under high pressure.

In this system, every cylinder works independently, so they do not fail together. Their high-pressure fuel injection of up to 1800 bar makes them suitable for heavy-duty diesel engines. Also, inline pumps are simple in design and construction and, as a result, are easy to maintain and repair in remote areas. Inline fuel pumps have better torque and can withstand tough working conditions. These reasons make them a popular choice for Indian farmers. However, they are less efficient and produce higher emissions than advanced fuel pumps like CRDI. Some popular tractors with inline fuel pumps are New Holland Excel 5510 and John Deere 5210 Gear Pro.

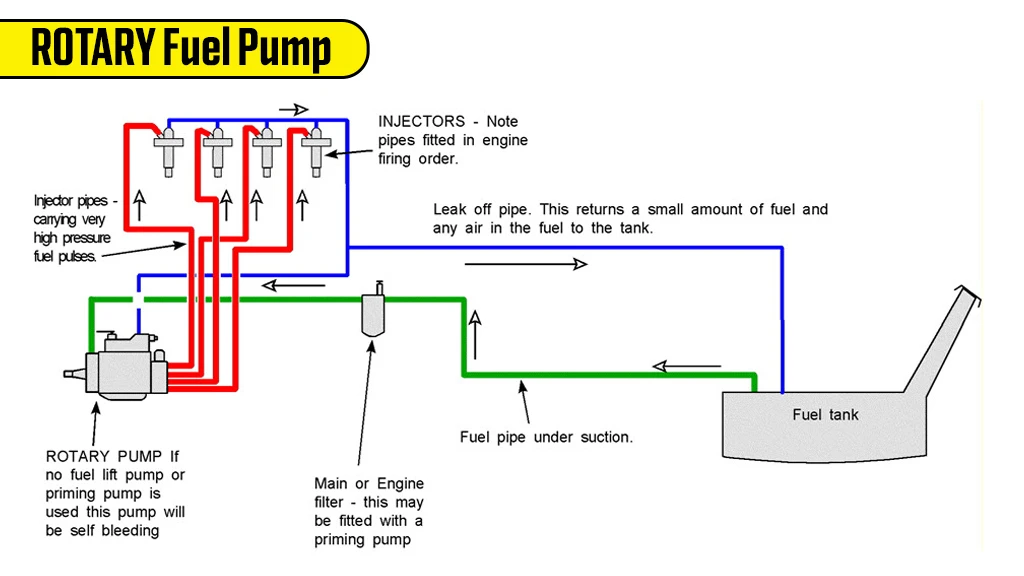

Rotary Fuel Pump

Rotary pumps, also referred to as distributor pumps, use a rotor to distribute fuel to every cylinder. The engine camshaft drives these pumps. There are circular output lines on rotary fuel pumps, including suction and delivery ports. As the rotor rotates, the intake metering port aligns with the suction ports, while the delivery ports align with the distribution port. Unlike an inline pump, there is only one plunger with a reciprocating movement to deliver fuel to all cylinders.

This rotary pump has a single rotor and individual high-pressure pipes to deliver fuel to multiple cylinders. So, they receive an equal amount of fuel, resulting in uniform fuel combustion based on the firing order. This generates consistent power strokes. A rotary pump is compact and thus weighs less. Thus, they are suitable for modern tractors with limited space. New Holland 3630 TX Super is a popular tractor that feature a rotary fuel pump.

However, as only one plunger generates force for fuel delivery, the pressure produced by a rotary pump is lesser than that of inline pumps. Thus, they are not ideal for heavy-duty tractors.

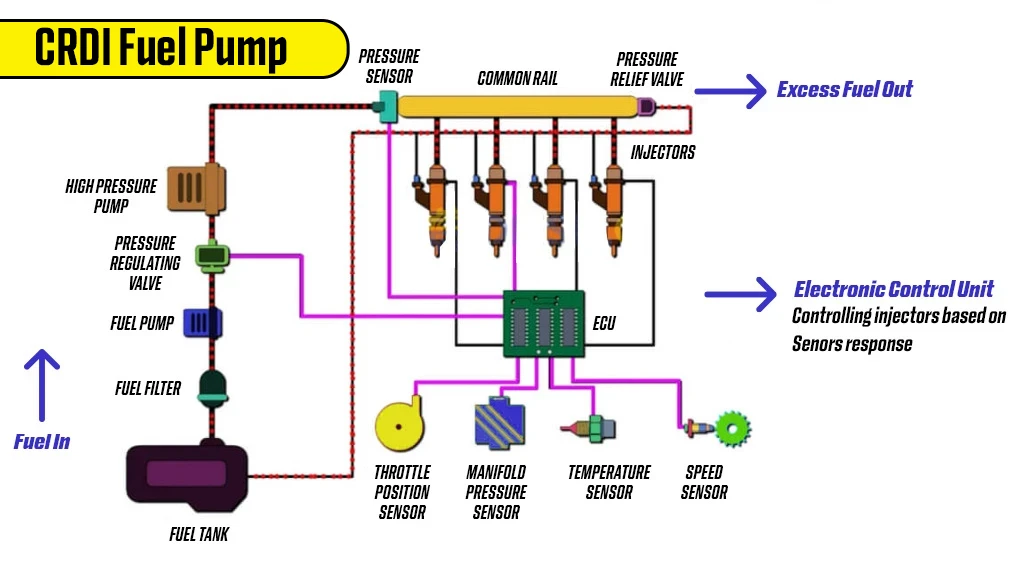

CRDI Fuel Pump

CRDI Pumps are the most technologically advanced fuel pumps used in a tractor. Now, most tractors with above 50 HP power output are equipped with CRDI fuel pumps as tractor manufacturers in India have been mandated to comply with the Trem IV emission norms from January 2023. In the Common Rail Direct Injection (CRDI) system, a common fuel rail supplies pressurised fuel to individual injectors, thus allowing precise control over fuel injection timing and pressure.

Its function involves storing fuel in the common rail at a high pressure of around 1,000 to 2,500 bar. Electronic Control Unit (ECU) is the brain of this CRDI system as it considers different parameters like engine speed, RPM and load to determine the suitable time for injecting fuel into each cylinder. When the ECU triggers injection, fuel injectors supply fuel in a precise amount into the combustion chamber.

CRDI pumps offer excellent fuel efficiency, resulting in lower operating costs for tractor owners. They precisely control fuel injection, optimising combustion for improved power, torque and lower emissions. Some modern CRDI tractors available in the market are Sonalika Tiger DI 60 CRDS 4WD and Mahindra Novo 605 DI V1.

However, as these pumps use advanced technology and sensors, CRDI tractors are often more expensive than rotary or inline pumps. Also, they are highly sensitive to fuel quality. Due to the use of electronic components, their use in wetlands becomes limited. Their service and maintenance require specialised training and equipment.

Maintenance and Troubleshooting of Fuel Pumps

Regular maintenance and inspections of the fuel pump are important to ensure the tractor runs smoothly and efficiently. Here are some tips for maintenance and troubleshooting:

- Check fuel lines for leaks, clogs or damage regularly. Replace any damaged components promptly.

- Clean or replace the fuel filters at regular intervals based on inspection or as mentioned in the manual.

- Check if the water level has reached the mark on the water separator. If yes, open the drain plug and remove all the water.

- Clean the fuel tank thoroughly after emptying it to ensure no contaminants get mixed in the fuel.

Now you see how important a fuel pump is for the engine. It not only ensures precise fuel delivery but also impacts the performance and fuel efficiency of the tractor. It is important to understand the type of fuel pump used in a tractor to decide if it is suitable for your farming needs. Regular maintenance of the fuel pump system helps prevent issues and keep the tractor running smoothly, ensuring high farm productivity for a long time.

Related Blogs