Ballasting in a Tractor: Everything You Need to Know

Table of Contents

- What is Ballasting and Why is It Important?

- How to Ballast Your Tractor?

- How to Check the Appropriate Ballast?

- Things to Keep in Mind While Ballasting Your Tractor

What is Ballasting and Why is It Important?

Tractors are often used with various implements, and their weight distribution can significantly impact their functionality. Therefore, ballasting comes in the picture. Ballasting refers to adding additional weight to the drive wheels or tractor for mainly providing more stability to the tractor.

It reversibly increases the mass of your tractor, the more the mass, the better the traction. The addition of ballast to a tractor is done commonly by adding wheel weights, adding front weights, and filling the tyres with water. It provides extra traction and prevents wheel slippage. Ballasting becomes quite essential when you have a light weight tractor which you use for activities that require more traction like ploughing or puddling. It is also useful in sloping land conditions or vineyards. Ballasting reduces soil damage, reduces fuel consumption, increases work efficiency, reduces working time, and enhances the life of your tyres.

How to Ballast Your Tractor?

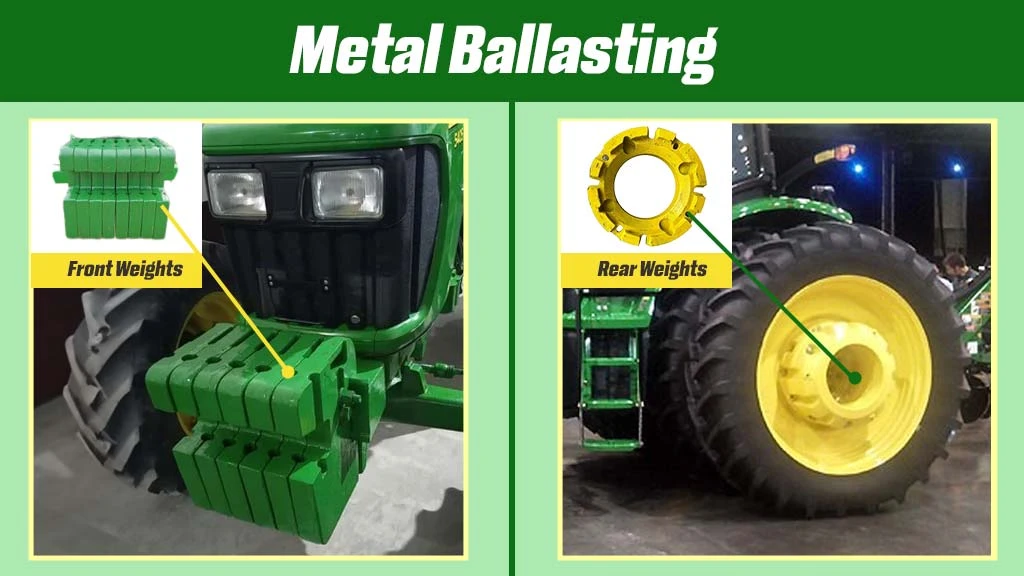

There are two ways to ballast in a tractor, one is ballast with metal weight and the second one is to ballast the tyres with water. You are supposed to choose the ballasting type on the basis of your usage. Let’s look into them one by one for better understanding:

Metal Weight Ballast

Metal weight ballast includes adding metal weights, made of usually cast iron, on the tractor or on its wheels and axle. Metal weight ballast is a suitable ballast option if you want to spread the load between both front and rear of your tractor as it is not possible to achieve this with water ballasting.

Usually, a distribution of 40% to the front and 60% to the rear is recommended. You are required to take into account the weight of implements which also produce and transfer a certain load to the rear axle. If you are required to pull a light load with your tractor then most of its weight should be on the rear. In case you are required to pull a heavy load then the weight should be spread in the appropriate proportion between both front and rear. Refer to the weight distribution table below:

|

Tractor |

Light Load |

Heavy Load |

|

Front Rear |

Front Rear |

|

|

2WD tractor |

25% 75% |

35% 65% |

|

4WD tractor |

35% 65% |

40% 60% |

You can do metal ballasting by adding additional weight to its wheels or at the front of the tractor. You can begin by adding metal discs to the wheel discs and then securing them with bolts. Wheel ballast sometimes leads to the issue of tractor lifting from front which can be resolved by front ballasting. You need to install starter weight firstly and then add appropriate weight as required. They are also quite easy to adjust as you can add or remove the cast weights according to your farming requirements.

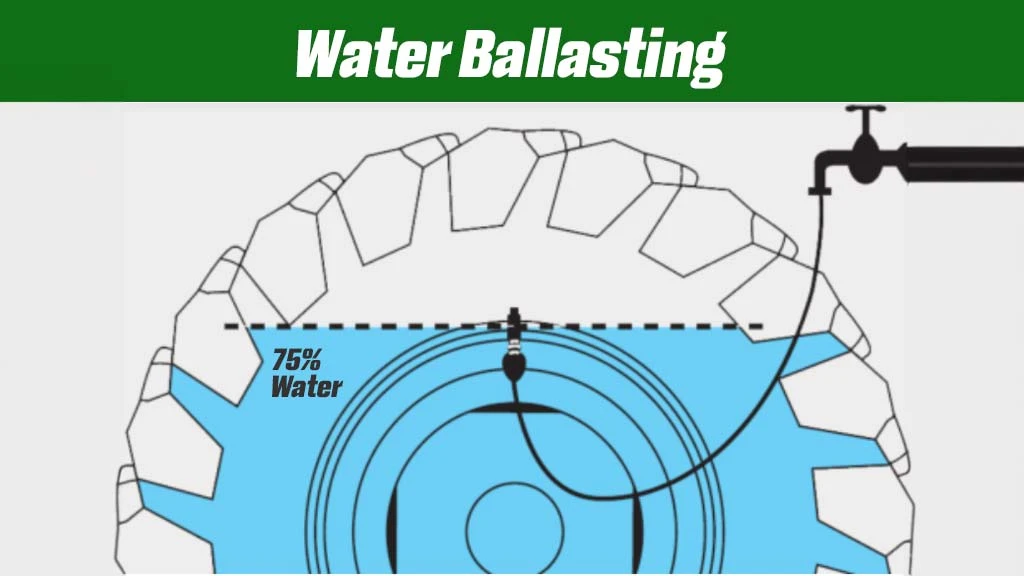

Water Ballast

Water ballasting is a suitable option to choose if you wish to ballast your tractor permanently. It is done to reduce slippage of rear tyres by filling water in the rear tyres. However, you are not supposed to completely fill the tyres with water as it can damage the tube or tyre. The water to air ratio should be 75:25. It is important to note that you will not be able to adjust the loads in water ballasting like in metal ballasting. This option is more economical than metal ballasting and there are no risks of mechanical breakdowns of the front axle. Follow the steps below for appropriate water ballasting:

- Firstly, jack up the wheel and hold the valve at 12 o'clock position.

- Then gently remove the valve to release the air. Proceed by using force to fill the tube completely with water.

- You are then supposed to rotate the wheel and bring the valve at the 10 o'clock position. This will spill out the extra water and approximately 75% water will remain in the tube.

- Now, hold the valve again at 12 o’clock position and close the valve. Thereafter, fill the air to maintain the pressure of 14 to 16 PSI.

Please make sure to refer to your manufacturer's guidelines before ballasting the tyres.

How to Check the Appropriate Ballast?

You can check the ballast by observing the tread marks on the soil.

- If the tread mark is not clearly defined as shown in figure (a) then this means there are chances of a high rate of slipping as it is insufficiently ballasted.

- If the tread marks are too deep as depicted in figure (b) then there will not be much slippage but this can cause more soil compaction.

- Clearly defined surface tread marks as shown in figure (c) indicate there is sufficient ballast.

Things to Keep in Mind While Ballasting Your Tractor

Tractor ballasting offers a lot of benefits, however, it is also important to take care of a several things while practicing tractor ballasting:

- Tyres that are excessively overloaded can become irreversibly deformed and can cause defects or punctures due to which they would be required to replace prematurely.

- Too much load increases rolling resistance and slip which will lead to more fuel consumption and less productivity.

- If the total weight of the tractor is excessive for the tyres then there are chances of increased risk of road accidents while haulage. It is due to its impact over the braking system.

- It is important to do frequent pressure checks in water ballasting because of the air volume reduction in the tyres. Even the slightest loss of more air can lead to more decrease in pressure which ultimately can be damaging.

Tractor ballasting is a requirement when you are working with heavy implements which require a lot of torque. However, one should practice ballasting by making sure that the manufacturer’s recommended load at normal inflation pressures is not exceeded.

Related Blogs