Step-by-Step Process for Attaching a Plough to Your Tractor

Table of Contents

- An Overview of MB Plough

- Tractor Preparation Before Attaching an MB Plough

- How do you Attach a Reversible MB Plough to a Tractor?

- Conclusion

An Overview of MB Plough

An MB plough is a tillage implement which breaks, turns, and mixes the soil and helps prepare seedbeds. It consumes more traction energy than any other implement. It works deep into the soil and helps in the proper germination of deep-rooted crops. Ploughing is done to add more fertility to the soil, control weeds, and provide greater root protection. Now, we have an idea for an MB plough, so let’s understand the entire process of attaching it to a tractor.

Tractor Preparation Before Attaching an MB Plough

Preparing the tractor is a necessary step before attaching an MB plough, as this enhances overall productivity and saves fuel. Let’s have a look at some important points to be considered before attaching an MB plough to a tractor:

- The front and rear tyres of the tractor should be aligned properly as they move in the same furrow.

- The next important point for preparing the tractor is that the tractor should have weight in the rear tyres. You can increase the weight either by additional weight or by filling 75% water and 25% air in the tyres.

- The tractor should have an auxiliary kit, and the selective control valves should be cleaned properly for seamless operation.

- Make sure that both the lower links of the 3-point linkage should be at the same height before attaching the MB plough.

- Select load and depth control settings according to the tractor operator manual.

How do you Attach a Reversible MB Plough to a Tractor?

Now that we have learned how to prepare the tractor, it's time to attach the MB plough properly. Making proper attachment and setting a hydraulic reversible MB plough will result in better penetration and efficient working. Let’s have a look at the steps for attaching an MB plough below:

Step 1: The initial step of attaching an MB plough is to place the tractor and the implement at the same ground level for proper attachment.

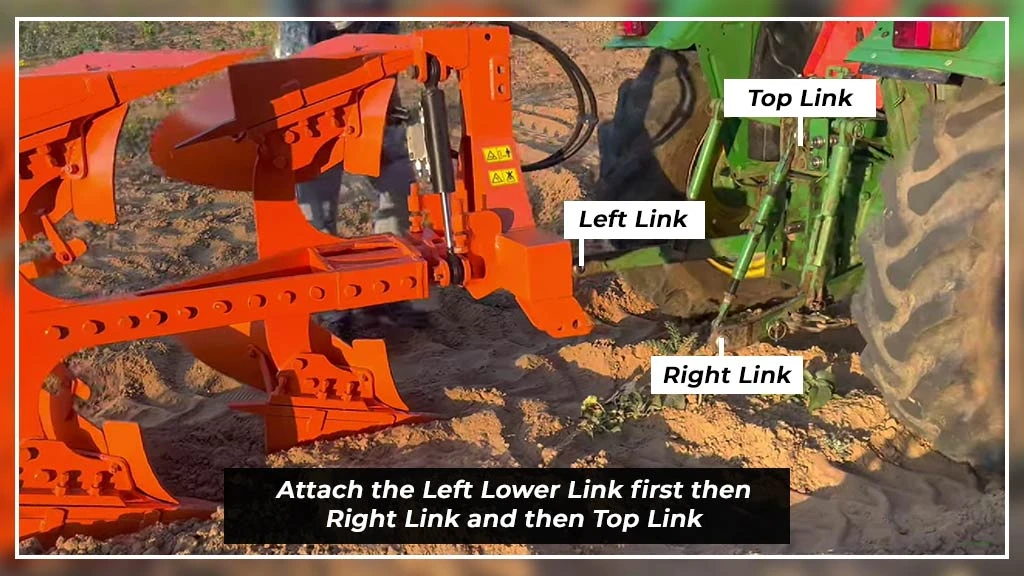

Step 2: Now, reverse the tractor and attach the MB plough with the help of a 3-point linkage.

Step 3: Always attach the left lower link first and secure it with a pin, then connect the right link, which is an adjustable link, so that you can adjust it when the tractor and implement are not at the same level during attachment. At last, connect and secure the top link.

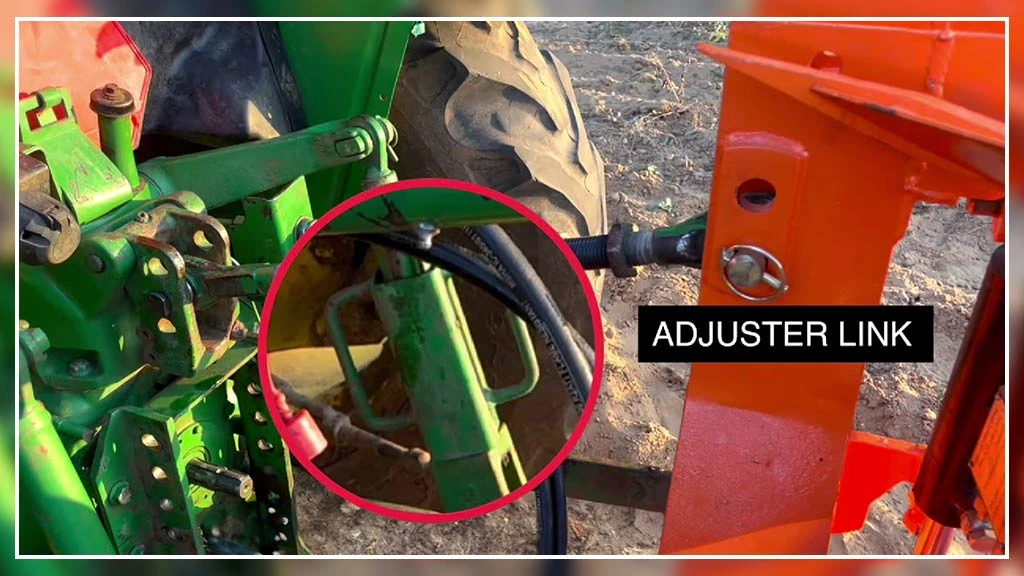

Step 4: Use the right adjuster link to align the MB plough along with the width and parallel to the ground.

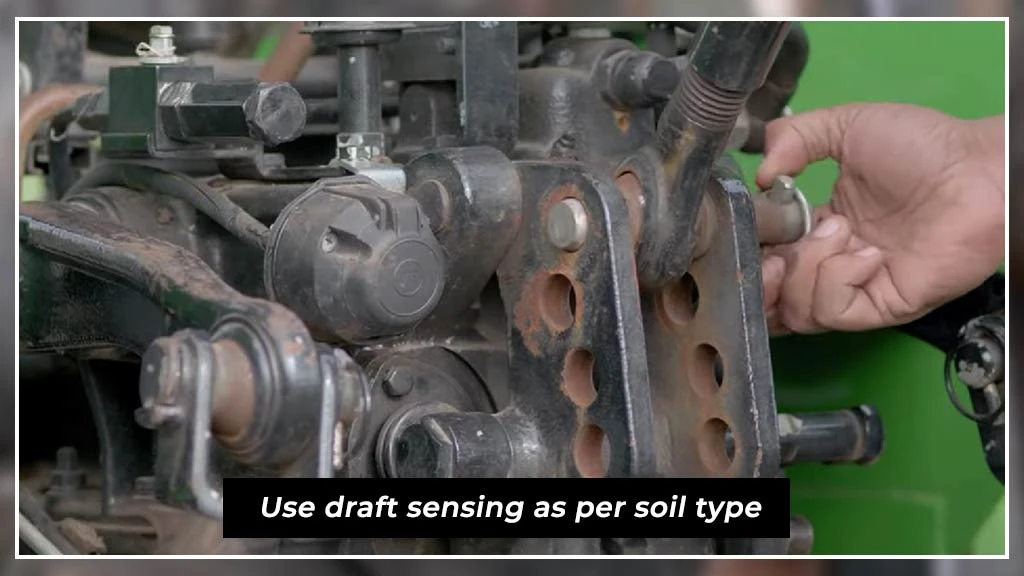

Step 5: There are different holes in the top link for the draft sensing. Place the top link in the lower draft sensing hole to work in hard soil, whereas it should be placed in the high draft sensing hole when working in light soil conditions (Please note: The top link sensing can vary from brand to brand. Hence, understand for your chosen brand which hole has high or low sensing)

Step 6: Check if the plough frame is parallel to the ground or not; if the frame is bent towards the back of the plough, shorten the top link, and if it is lifted, then lengthen the top link.

Step 7: Check the MB plough from behind and make sure that the leg assembly should be 90 degrees from the ground.

Step 8: The pull line adjustment is the final setting while attaching an MB plough. The line between the center point of both the lower links and the center point of the cutting edge of the plough is called the pull line. If it passes through the middle of the rear axle of the tractor, then the plough is moving in the right direction, and if it does not pass through the center of the rear axle of the tractor, then adjust the plough by shortening or lengthening the inner turnbuckle of the Opti quick to make the tractor working without pulling in any direction.

Step 9: Now, you are all set to work with an MB plough in your agricultural field.

Conclusion

Now, we have come to an end, and hope that you understand the entire process of attaching the hydraulic reversible MB plough to a tractor. Always take all the necessary steps while working with an MB plough or any other implement with a tractor. Making proper attachments will increase the output and save your diesel, money and time. It is also important to complete the timely service of the MB plough to give it a longer life. Moreover, Tractorkarvan offers various tractors and MB ploughs from top brands, such as Fieldking, Lemken and Mahindra. You can light up your burden by taking an Implement Loan with easy EMI options to buy MB ploughs from us. Tractorkarvan will help you in the future with more tractors and implement-related blogs, so stay tuned for further updates.

Related Blogs