Choose the Best Thresher for your Farm: Types & Top Threshers in India

Threshing has been practiced in India for many years. It can be done manually or with the help of machinery. However, manually threshing takes a lot of time and human labour. So, a thresher is necessary for all agricultural mechanization. In this blog, we will explore the top threshers available in India, their types, uses and safety precautions taken while operating the machine.

Table of Contents

- An Introduction to Thresher Machine

- Types of Threshers in India

- Components of Thresher

- Top 8 Threshers in India

- Safety Precautions while operating Threshing Machine

An Introduction to Thresher Machine

A threshing machine or a thresher is an agricultural implement that separates the grains from husks or straw (bhusa). It is an essential implement to increase the productivity of the crops without any loss or damage. Due to the accurate separation of the grain and the husk, the farmers will get better grain quality. As this is a machinery process, it saves time and human labour. The thresher can be used to thresh various crops such as wheat, paddy, soybean, etc.

The first thresher was introduced in India in 1956-57, named as the “Ludhiana Thresher”. This thresher was tractor-driven and was mainly used for wheat cultivation. After this, less-HP threshers started developing in 1960s. The spike tooth cylinder thresher was widely used then and commercially marketed in the country around 1970. After 1970, harvesters started invented and began to use for threshing, but compared to harvesters, threshers are more economical for farmers.

Types of Threshers in India

There are different types of threshers available in the market. Let’s have a look on the different types of threshers below.

Single Crop Thresher

A single crop thresher is mainly used for a grain such as wheat. It threshes, separates and cleans the grain by making the suitable “bhusa” for animal feeding. These threshers are economical as compared to multi crop threshers. They are compatible with less HP tractors.

Multi-Crop Thresher

A multi-crop thresher is an essential and most popular thresher among Indian farmers. This thresher is used for most crops, such as wheat, moong, paddy, grain, soybean, etc. There is a high demand for this type of thresher as a single machine can thresh many crops. Bruised straw (bhuna) is the main requirement of wheat crops, whereas farmers require long straws for paddy. For pulses, seed damage should be minimal during the threshing process, as damaged seeds lower the quality of the grain. So, a multi crop thresher can do all these tasks while a single crop thresher is not an ideal option if you want to thresh multiple crops.

Haramba Thresher

Haramba threshers are also known as “high-capacity” threshers. These threshers are designed in a way where a platform is attached to the machine, and a person stands and feeds the crop into the thresher from the top, then, it separates the grain with the help of sieves, and the husk is blown through the fans. It can also be used to thresh crops with high moisture content. The machine is easily operated by PTO of minimum 35-hp tractor.

Basket (Tokri) Thresher

The Basket or Tokri thresher, a multi-crop thresher, is a game-changer for farmers. With its attached basket for easy feeding, it not only separates the grain from the straw but also throws it to a distance of 20-25 ft. More importantly, it significantly reduces the labour involved in the threshing process, saving farmers precious time and money.

As we have discussed all four types of threshing machines, we also need to know that some threshers are further classified based on functional components and types of threshing cylinders. Let’s have a look.

- Functional Components

- Drummy

- Axial flow

- Regular (Through-put)

- Types of Threshing Cylinders

- Syndicator

- Spike tooth type

- Rasp bar type

- Hammer Mill or Beater type

Components of Thresher

The main components of threshing machines are drive pulley, feeding chute, cylinder, spikes, fan or blower, flywheel, concave, frame, lower sieve, upper sieve, frame, suspension lever, transport wheel, shutter plate and can pulley.

Top 8 Threshers in India

|

Thresher Model |

Required Tractor (in HP) |

Crop Type |

No. of Fans |

|

45+ |

Wheat |

4 |

|

|

35+ |

Paddy |

2/4/5/6 |

|

|

35+ |

Multi-crop |

2 |

|

|

Harnam Multi Crop Hopper Model

|

50+ |

Multi-crop |

4 |

|

35+ |

Multi-crop |

NA |

|

|

35+ |

Wheat |

3/4 |

|

|

50+ |

Multi-crop |

4 |

|

|

40+ |

Multi-crop |

4 |

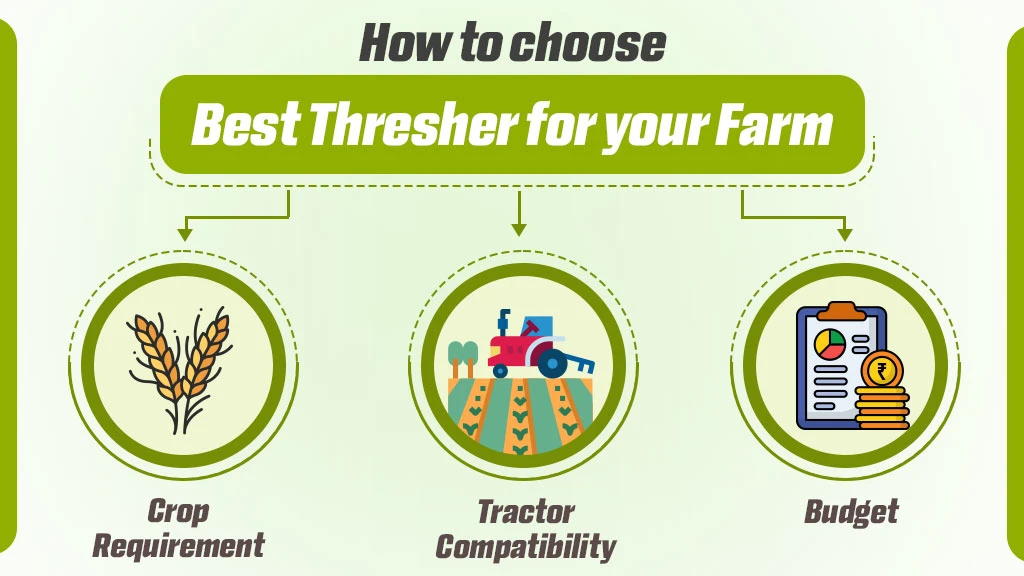

How to Choose the Best Thresher for your Farm

Crop Requirement – Crop requirement is the first and foremost step when choosing the thresher for your agricultural farm. Different threshers are used for different crops so, if you want to thresh a single crop such as wheat, you should buy “Single Crop Thresher” or if you have a large farm and a variety of crops to thresh, then you can go for “Multi Crop Thresher”. So, choose your thresher according to the crop requirements.

Tractor Compatibility – Choose your thresher as per engine HP and the power take off (PTO) of the tractor. A single crop thresher work with lesser HP tractors while the multi crop thresher will require a higher HP tractor. So, these factors are necessary while choosing the thresher for your tractor.

Budget - Always choose your thresher according to the budget. Look for the subsidies provided by the government or you can also take an implement loan on easy EMIs from Tractorkarvan.

Safety Precautions while operating Threshing Machine

- Do not feed ear-heads without stalks, as it leads to hand injuries.

- Ensure there are not any obstructions while working with the thresher.

- Do not wear loose clothes, bangles and wrist watches while working on a thresher.

- Set proper lighting when working during night, as poor visibility might cause unusual incidents.

Frequently Asked Questions On Choose the Best Thresher for your Farm: Types & Top Threshers in India

1. What are the key features to consider when choosing a thresher machine in India?

The key features which should be considered when choosing a thresher are crop requirement, tractor compatibility, thresher capacity, farm size, and durability.

2. What is the use of the thresher?

A thresher is used to separates the grains from husks or straw (bhusa).

3. Which are the popular brands that offer the best thresher machines in India?

The popular brands of threshers include Mahindra, Harnam and Reinforce.

4. What types of crops can be threshed using thresher machines?

A variety of crops can be threshed using threshers such as wheat, paddy, soyabeans, etc. depending upon the type of thresher.

Related Blogs