Know Everything About Trem IV Tractors and CRDI technology

Common Rail Direct Injection (CRDI) engine is among the latest technological development for the Indian tractor industry. The CRDI technology ensures precise and timely delivery of fuel to offer benefits like improved performance, high fuel efficiency and lesser emissions. The Indian government has mandated CRDI engines for all tractors above 50 HP to meet the Trem IV emission standards. Read on to learn more about CRDI engines, how they work, and their advantages and disadvantages.

Table of Contents

- Introduction to CRDI Technology

- What is CRDI Technology?

- How does a CRDI Engine work?

- What are the Advantages of CRDI Engine in Tractors?

- What are the Disadvantages of CRDI Engines in Tractors?

- What is the Future of CRDI Tractors in India?

- What are the Top Tractor Models in India with CRDI Engines?

Introduction to CRDI Technology

Automotive engineering is constantly making efforts to improve fuel efficiency and engine performance while controlling emissions. Common Rail Direct Injection (CRDI) technology is a huge breakthrough in achieving these goals. It has reformed the functioning of diesel engines to produce improved performance and reduce harmful environmental impact.

CRDI tractor engines are a step towards achieving carbon neutrality across the globe. Different tractor brands use different terminology for their CRDI engines. For example, John Deere refers to it as High-Pressure Common Tail (HPCR) technology. Farmtrac calls it e-CRT, while Sonalika uses CRDS for its CRDI tractors.

What is CRDI Technology?

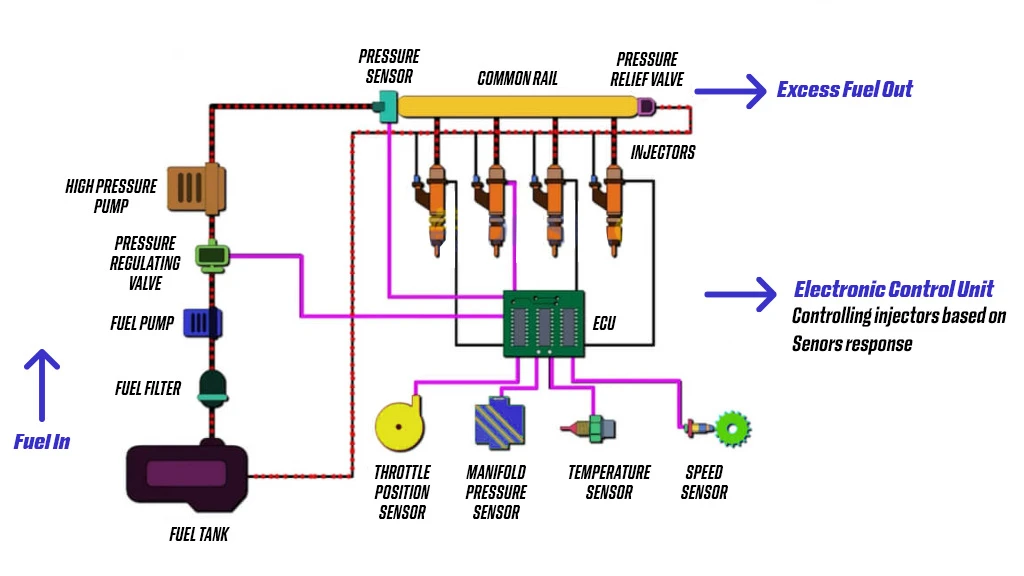

First, let's clear the common misconception about CRDI technology. A CRDI engine does not mean a new type of engine. It simply denotes a fuel injection system that uses multiple sensors and ECU to deliver fuel to cylinders. A common rail supplies fuel to injectors at high pressure. The ideal duration and timing of fuel injection are controlled by ECU, resulting in improved fuel efficiency and lower emissions.

Contrary to older diesel engines, a CRDI engine has a high-pressure fuel pump. The main components of a CRDI engine are:

- Common rail

- Electronic Control Unit (ECU)

- Injectors

In the 1960s, Robert Huber developed the common rail system prototype. With further developments, common rail diesel engines were perfected for road vehicles. In 1995, Japan became the first country to manufacture heavy-duty trucks with the common rail on a large scale. Today, CRDI technology is available for all kinds of vehicles, ranging from passenger cars to farm tractors.

How does a CRDI Engine work?

The function of a CRDI engine can be broken down into three key steps:

Common Rail - Fuel Collection

As mentioned before, the CRDI technology offers high-pressure fuel injection system. This fuel pump moves fuel from the fuel tank to be stored in the common rail under high pressure ranging from 1000 – 2500 bar. The common rail can be considered a distribution system for pressurised fuel. It maintains constant fuel pressure and optimises injection accuracy as well as engine performance. The function of ECU comes in only when fuel is in the common rail.

Precise & Dynamic Fuel Injection

The ideal amount of fuel required by the engine cylinders depends on a wide range of parameters. It is important to consider the engine load and torque to derive the correct amount of fuel to be supplied to combustion chambers. ECU obtains data from different engine sensors to calculate the precise amount of fuel required inside the cylinder. Thus, the ECU is the brain of the CRDI engine that controls the fuel flow into the chamber. As the common rail keeps pressurised fuel, the cylinder receives small droplets of fuel.

Efficient Combustion

The fuel injectors deliver a precise amount of fuel in the form of droplets to the combustion chamber. These fuel droplets mix well with the air and cause optimised combustion. In older diesel engines, the performance would highly depend on the fuel-air ratio as they work with bigger fuel droplets. This is why they faced issues like high noise levels and inconsistent power delivery. CRDI engines have better, more efficient combustion that ensures better overall performance.

What are the Advantages of CRDI Engine in Tractors?

There are several reasons to switch to CRDI engines. The following are the main advantages of CRDI technology over conventional diesel engines:

- Improved Performance: The precise and timely delivery of fuel in CRDI engines improves the engine responsiveness and power output. As they deal with refined fuel spray, these engines deliver consistent power delivery.

- Better Fuel Efficiency: CRDI engines use different sensors to deliver only the necessary amount of fuel to the chamber. Thus, there is no fuel wastage, which leads to ideal fuel consumption. Better management of fuel injection and steady power delivery results in better fuel efficiency.

- Engine Refinement: CRDI technology improves the noise, vibration and harshness (NVH) of the tractor. The engine runs smoother and quieter. This is mainly because of controlled injection on time. These engines use a finer fuel spray, which burns efficiently.

- Reduced Emissions: CRDI engines are a boon for the environment. Due to the unoptimized use of fuel in older engines, these tractors produce a lot of black smoke. It is harmful to the health of both the environment and people. Thus, CRDI tractors produce fewer emissions, which is valuable for the healthy future of the planet.

- Engine Durability: The engine life of CRDI tractors increases because controlled fuel injection does not put excessive stress on its components. A stable fuel spray enhances engine refinement, which leads to smoother operation. Additionally, the engine tends to experience less wear and tear. Thus, CRDI engines have better durability than traditional diesel engines.

What are the Disadvantages of CRDI Engines in Tractors?

Even with several benefits, CRDI engines are not perfect. Here, we have listed some key demerits of using CRDI engines in tractors:

- Higher Cost: A CRDI engine is costly for both the manufacturer and the customer. It uses more parts than conventional diesel engines. In addition, they require advanced components like pressure sensors and computer chips. This is why CRDI engines are expensive to manufacture. Also, a costlier engine will result in a costlier tractor, which is not ideal for customers.

- Complicated Construction: A CRDI engine is an advanced piece of machinery. Thus, maintaining and repairing it is challenging. Only authorised and skilled workers can diagnose and resolve the issue in case of any fault. This becomes troublesome if a farmer is working in a remote location. Also, their repair is costly because of their expensive components.

- Limited Operations: As CRDI engines use electrical components, they are susceptical to damage from water. Thus, these tractors are not recommended for operations in water-filled fields. CRDI engines are also sensitive to the quality of fuel. So, uncontaminated fuel can easily result in major issues in the engine.

Farmers can choose to buy a CRDI tractor, considering the merits and demerits of CRDI engines. However, if you are interested in a tractor with a power output of more than 50 HP, you will have to buy a CRDI tractor. This is because CRDI engines are mandatory for more than 50 HP tractors to meet the Bharat Stage TREM IV standards set by the Indian government.

What is the Future of CRDI Tractors in India?

CRDI tractors are a big step towards revolutionising the Indian farming sector. They have several benefits over traditional diesel engines, like enhanced performance, improved fuel efficiency and reduced emissions. Even though non-CRDI engines will be available in tractors, it makes sense to adopt CRDI technology to remain technologically-updated. Also, it is important to comply with the Trem IV emission standards to control environmental pollution. Additionally, farmers will benefit from CRDI tractors with better fuel efficiency and more reliability.

What are the Top Tractor Models with CRDI Engines?

Here are some top tractors in India that feature CRDI engines:

|

Model Name |

Tractor Power (HP) |

|

65 |

|

|

60 |

|

|

60 |

|

|

57 |

|

|

55 |

If you need more information about CRDI tractors, you can check out the Top 10 Trem IV Tractors for Farming in India. You can also check out a wide range of CRDI tractors on Tractorkarvan, including their prices, key specifications, and features. Choose a suitable model and boost your productivity and efficiency right away.

Related Blogs