What is Seed Drill: Components, Calibration Process & Benefits

Traditional broadcasting involves scattering seeds by hand, and it is an highly laborious method of sowing seeds. A seed drill has transformed the sowing process by planting seeds at precise depth and spacing. Also, it is a crucial farm machinery for saving time, labour, and seeds. Let’s dig deeper into different aspects of a seed drill, including its components, calibration, and benefits, to reshape your farming.

Table of Contents

- What is a Seed Drill?

- How to Attach a Seed Drill to the Tractor?

- What are the Different Types of Seed Drill?

- What are the Main Components of a Seed Drill?

- How to Calibrate a Seed Drill?

- What are the Benefits of a Seed Drill?

What is a Seed Drill?

A seed drill is an implement used by farmers to sow seeds in rows at uniform depths and spacing. Along with this, it also applies fertilizers and covers the seeds with soil. This machinery allows precise, efficient sowing, ensuring seeds are sown in the soil where germination is possible. A seed drill transforms planting practices to help achieve high crop yields with minimal seed wastage. Scattering seeds by hand is a traditional method that not only wastes seeds but also does not ensure ideal growth conditions for them. Using a seed drill enhances productivity by eliminating manual labour and improves germination to achieve higher crop yields.

How to Attach a Seed Drill to the Tractor?

It is important to understand how to attach a seed drill effectively for safety and efficient sowing operations. This process involves the use of the three-point hitch system of the tractor.

- Make sure the tractor is on a levelled surface.

- Position the seed drill directly behind the tractor.

- Align the mounting points of the seed drill with the 3-point hitch of the tractor.

- Connect the lower pins of the seed drill with the lower lift arms. Also, connect to the top link and adjust it for levelling the seed drill.

Ensure that the seed drill is attached securely, and all the bolts and pins are tightened properly for field applications. Note that in the case of super seeders, roto seed drill, and pneumatic precision planter, power is needed for different mechanisms. So, the input shaft of these seed drills needs to be connected to the PTO shaft of the tractor.

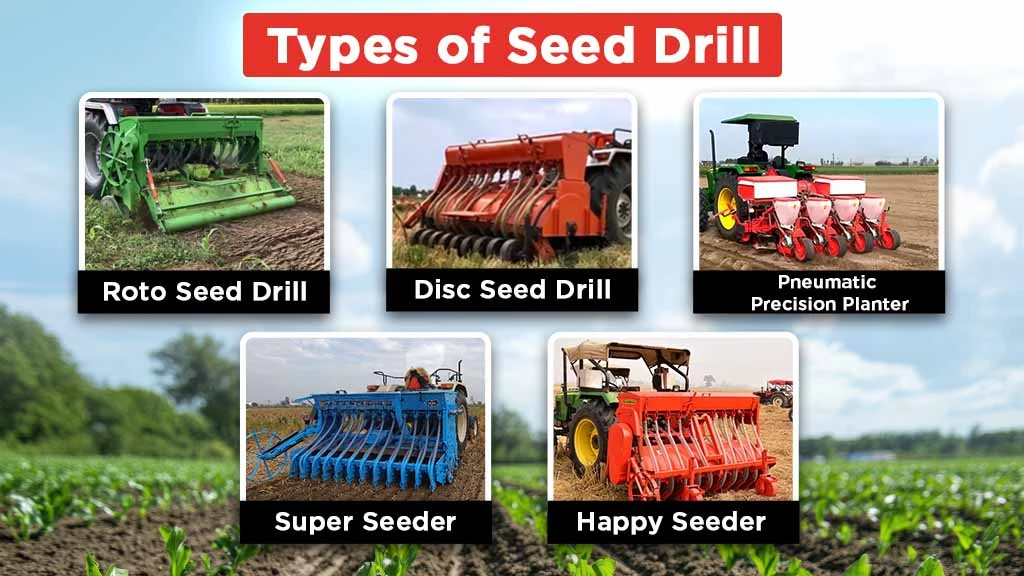

What are the Different Types of Seed Drill?

- Roto Seed Drill: It performs the tasks of both rotary tiller and seed drill. Its rotating blades till the soil, and the seed drill function ensures seed sowing and fertilizer application.

- Disc Seed Drill: With angled steel discs, it cuts through the soil to create furrows and sow seeds and apply fertilizer.

- Pneumatic Precision Planter: This type of seed drill ensures precise seed sowing by picking up seed using air pressure and sowing them into the soil accurately at a suitable depth and spacing.

- Super Seeder: A super seeder performs multiple operations to till, sow, and cover the seedbed in a single pass. This implement is mainly used for sowing during wheat cultivation in combine-harvested paddy fields.

- Happy Seeder: A happy seeder is used to sow wheat directly into an unploughed field covered with residues left after the previous harvested crop. Thus, there is no need to burn the leftover straw.

What are the Main Components of a Seed Drill?

- Seed box: Stores the seeds to be sown.

- Seed metering mechanism: Placed at the bottom of the seed box, it regulates how many seeds are dispensed from the box. The following are the different seed metering mechanisms:

- Fluted feed type

- Internal double run type

- Cup feed mechanism

- Cell feed mechanism

- Brush feed mechanism

- Picker wheel mechanism

- Star wheel mechanism

- Auger feed mechanism

- Frame: This rugged metal frame holds all other components of the seed drill.

- Furrow openers: Cuts the soil at a uniform depth to form furrows where seeds will be sown.

- Drive transmission system: Delivers power to the seed metering mechanism from the transport wheels.

- Covering device: Closes the furrows by covering them with soil after the seeds have been placed.

- Transport wheels: Allow moving the seed drill around the field.

How to Calibrate a Seed Drill?

Seed drill calibration is an important process to ensure the distribution of the correct amount of seeds per unit area at the proper spacing and depth. It maximizes yield by preventing seed waste and facilitating uniform germination. You can make changes to the gearing of the ground wheel to determine the seed rate of the seed drill. The procedure for calibrating a ground wheel-driven seed drill is as follows:

- The first step is to calculate the nominal width (N) of the seed drill by multiplying the number of furrow openers (M) by the spacing between openers (S) in meters.

W = M * S

- Then, determine the strip length (L) with nominal width. If you have 1 hectare (10000 m²) of area:

L * W = 10000

L = 10000 / W (meter)

- To calculate the number of revolutions (N) needed by the ground wheel to cover the strip length (L):

L = P * D * N = 10000 / W

So, N = 10000 / P * D * W revolutions per minute

- Use a jack to lift the seed drill off the ground to turn the ground wheel freely. Mark the drive wheel and the body of the drill to help count the revolutions of the ground wheel.

- Fill the hopper with seeds and put a container under every boot to collect seeds dispensed from the seed hopper.

- Adjust the seed rate control for the maximum position to be marked on the control for reference.

- Rotate the ground wheel by engaging the clutch for N revolutions per minute.

- Record the weight of seeds collected in the container.

- The last step is to calculate the seed rate (kg/ha). If it is less than or greater than the desired rate, adjust the seed rate control and repeat the process until you get the desired seed rate.

What are the Benefits of a Seed Drill?

- A seed drill offers precision and uniformity in seed sowing at consistent depth that ensures efficient delivery of resources to seedlings and plants, resulting in optimized growth and better yields.

- Due to the even distribution of seeds, seed wastage is minimized, which means more savings for farmers. It also contributes to the efficient use of resources like fertilizers and pesticides.

- This implement reduces the amount of labour and time needed to sow seeds as it can cover large areas quickly.

- Weed control becomes easy by the precise placement of seeds, as targeted application of herbicides becomes possible.

- With minimal soil disturbance, it promotes soil health and prevents soil erosion. Also, proper use of resources is a part of sustainable agricultural practices.

A seed drill is a precision implement that sows at the perfect depth and spacing. It needs to be calibrated for accurate seed & fertilizer application rates and optimized resource allocation. Using a seed drill offers a range of benefits, including crop uniformity, reduced seed wastage, and increased germination rates. Apart from this, it also enhances soil health and sustainability. Explore a wide range of seed drills on Tractorkarvan and boost your productivity now.

Related Blogs